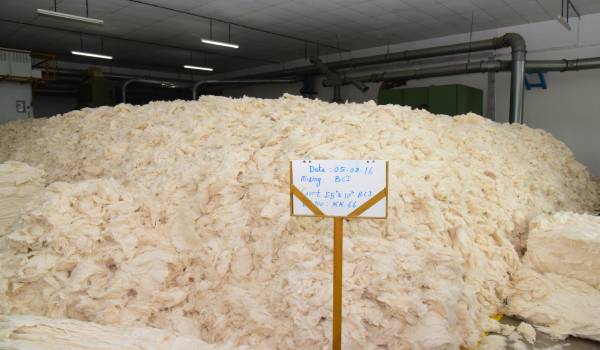

COTTON SELECTION

Raw cotton is an agricultural commodity and the quality, color, staple length, strength etc. of the cotton depends upon climatic conditions.

Raw cotton is an agricultural commodity and the quality, color, staple length, strength etc. of the cotton depends upon climatic conditions.

The selected raw cotton and recycled cotton are mixed with each other according to the count to be manufactured. The ratio of mixing is varied from time to time and count to count.

The mixed cotton is fed into the GBR (Super Bale opener) of the Blow room and is cleaned and beaten in step cleaner. Well equipped machine called ISCAN is been installed. Labours are well educated about the effects of contamination and trained suitably to remove maximum amount of contamination. All the micro dusts are removed in this process and the cotton is sent to Carding Machines.

All the Carding machines are TRUMAC COMPANY made High production and auto leveled cards. These are technically well in advanced and upgraded according to Global requirement. It is designed with energy saving devices and the result of this, the cost of power consumption is too low.

The Drawing machines role is a important one in the manufacturing of cotton yarn to avoid the thin and thick place in the yarn and also this is the most sensitive one which results in the High Production machine with quality parameters.

These machines are manufactured by M/s ELITEX, BD 200 SN MODEL. Machines and it is made by Czechoslovakia. In this OPEN END SPINNING MACHINES “SPIN BOXES” role is the vital one. Here the Drawing slivers are sent through the feed roll and further it is sent through the Opening roll of the Spin box. The Opening rolls are open the slivers and separate the Trash content and fiber. Finally the fibers are sent through the rotors and are twisted the yarn. At last, the entire process ends and the quality yarn is winded in the ceases.

The final OPEN END YARN is been manufactured according to various counts. According to the variation, the features are Eco-friendly and Smooth textured, excellent moisture absorbent capacity, Comfortable and skin-friendly, Fine finish and thickness.

The methods of twisting two or more single yarns are called doubling or folding or ply twisting. Such yarns are designated as doubled yarn, folded yarn or plied yarn and the machines intended for the purpose are called doublers or two-for-one twisters.

After the entire operation of yarn conversion ceases are collected in the baskets manually and send the same to the packing section where there is packed with woven sacks. The Individual cease weight is 2 KG. 32 Ceases are consisting of one bag (i.e) 64.kgs.

© 2019. Sri Jayakrishna Textiles

Design & Developed by IDI Infotech.